To the authors’ knowledge, there have been no review papers that summarize the biomedical applications of heterostructures prepared by additive manufacturing. This paper aims to highlight the research progress in additive manufacturing of promising heterostructure for bioimplants.

The unique interfaces, robust architectures, and synergistic effects inherent in heterostructures position them as a highly promising option for advanced biomaterials in meeting the stringent requirements for highly variable anatomy and complex functionalities from individual patients. However, the advancement of heterostructures has encountered obstacles in the precise control of crystal/phase evolution and distribution/fraction of components and structures.

Luckily, additive manufacturing, known for its high efficiency, design flexibility, and high dimensional accuracy, provides a strategic solution to regulate structure and composition across multiple scales, holding the potential for developing heterostructure with unprecedented properties. But an evident void exists in the scientific literature, as comprehensive review articles that summarize the biomedical applications of heterostructures via additive manufacturing are notably absent.

In a recent publication in the, International Journal of Extreme Manufacturing, Prof. Cijun Shuai and Prof. Chengde Gao’s team from Central South University addresses a critical gap in the literature by thoroughly examining the advances in additive manufacturing of promising heterostructures and their biomedical applications with an in-depth analysis of their structures, compositions, properties, advantages, processes and applications.

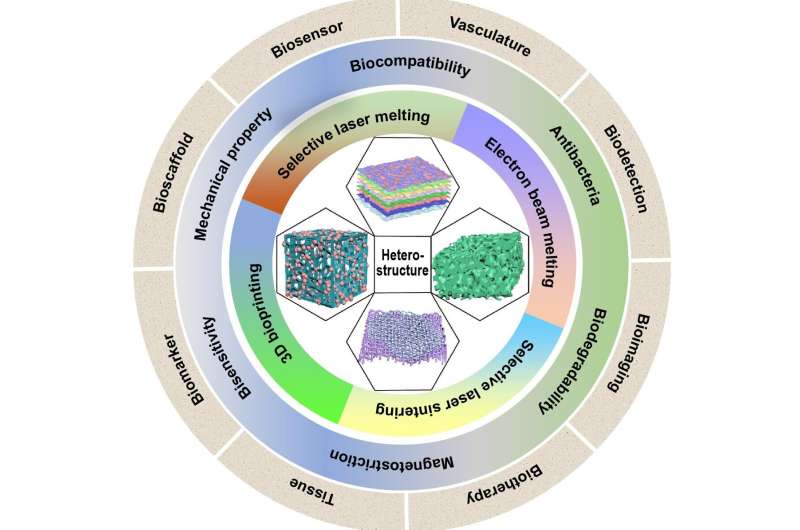

The synergistic effects arising from heterostructure through combining mechanical and biological performances are also summarized. This review offers a unique window into the promising utilization of heterostructure in biomedical fields, with particular attention to bioscaffolds, vasculatures, biosensors, and biodetections.

Heterostructure presents in form of macro/microstructural heterogeneity, crystalline heterogeneity, or compositional heterogeneity. “Especially, the synergistic performances of heterostructured biomaterials, particularly in terms of structures and compositions, is due to the clever development of special structures that span multiple properties,” said Cijun Shuai, a professor and the first author of the paper. These characteristics of heterostructure provide opportunities for bioimplants with multiple performance features.

Heterostructures not only overcome the inherent limitations of materials/structures but also allow the achievement the novel synergistic performances by proper combination.

“However, the main challenges of preparing heterostructure lie in the accuracy control of the crystal/phase evolution, as well as the distribution/fraction of components and structures of heterogeneous zones. Hence, more and more attempts and attentions have been devoted to the advance of novel processes for heterostructure, among which additive manufacturing has stood out due to the high flexibility,” said Chengde Gao, an associate professor and the corresponding author of the paper.

These are mainly functional mechanisms of heterostructure.

Additive manufacturing, normally referred to as 3D printing, is a “bottom-up” manufacturing approach and can prepare complex structural parts that were previously unattainable by traditional manufacturing methods.

“Hence, it offers new ideas and methods for the preparation of specific materials/structures due to high efficiency, design flexibility, and high dimensional accuracy. These characteristics enable additive manufacturing the capacity of strategically regulating the structure and composition at several scales, which provides a highly promising pathway towards developing heterostructure with unprecedented properties,” said Desheng Li, a Ph.D. student, and the other authors.

Despite the significant potential of heterostructures as promising solutions for biomedical fields, there are still some limitations that urgently need to be overcome. “On the one hand, the synergistic effects triggered by the multiple functional or strengthening mechanisms in heterostructure need to be in-depth investigated to determine their mutual effects on final properties introduced by the microstructural evolution and compositional alloying.”

“On the other hand, the heterogeneities of zones permit the exploration of many microstructural differences, such as more bio-inspired development of heterostructures from nature, towards the idealized goal of upgrading or replacing conventional materials. Finally, constructing the potential relationships of composition-structure-performance and uncovering the intrinsic synergistic effects by combining experimental, theoretical, and modeling studies that can be derived as design principles for heterostructured biomaterials,” said Cijun Shuai.

In brief, applying burgeoning additive manufacturing of heterostructure to infection prevention, pharmacy, and drug delivery is a worthwhile area for future research, which promises more breakthroughs and reformations in the biomedical field. These will bring many future benefits to humanity.

More information:

Cijun Shuai et al, Additive manufacturing of promising heterostructure for biomedical applications, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acded2

Provided by

International Journal of Extreme Manufacturing

Citation:

Examining advances in additive manufacturing of promising heterostructures and their biomedical applications (2023, December 5)

retrieved 6 December 2023

from https://phys.org/news/2023-12-advances-additive-heterostructures-biomedical-applications.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.